Product Description

Product Description

The reducer factory produces gearboxes with small size and high torque

WF series gearboxes for 5 axis machining center developed and manufactured by WEITENSTAN together with German and ZheJiang technicians for many years.

High precision miniature cycloidal gearbox has the characteristics of smaller, ultra-thin, lightweight and high rigidity, anti-overload and high torque. With good deceleration performance, smooth operation and accurate positioning can be achieved. Integrated design, can be directly connected with the motor, to achieve high precision, high rigidity, high durability and other advantages. It is designed for high speed ratio, high geometric accuracy, low motion loss, large torque capacity and high stiffness applications. The compact design (minimum OD ≈40mm, currently the world’s smallest precision cycloidal pin-wheel reducer) allows it to be installed in limited Spaces.

Product Parameters

| Size | reduction ratio | Rated output moment | Allowable torque of start and stop | Instantaneous allowable moment | Rated input speed | Maximum input speed | Tilt stiffness | Torsional stiffness | No-load starting torque | Transmission accuracy | Error accuracy | Moment of inertia | Weight | |

| Axis rotation | Shell rotation | Nm | Nm | Nm | rpm | rpm | Nm/arcmin | Nm/arcmin | Nm | arcmin | arcmin | kg-m² | kg | |

| WF07 | 21 | 20 | 15 | 30 | 45 | 3000 | 6000 | 6 | 1.1 | 0.12 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 0.52 | 0.42 |

| 41 | 40 | 0.11 | 0.47 | |||||||||||

| WF17 | 21 | 20 | 50 | 100 | 150 | 3000 | 6000 | 28 | 6 | 0.21 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 0.88 | 0.85 |

| 41 | 40 | 0.18 | 0.72 | |||||||||||

| 61 | 60 | 0.14 | 0.69 | |||||||||||

| WF25 | 21 | 20 | 110 | 220 | 330 | 3000 | 5500 | 131 | 24 | 0.47 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 6.12 | 2 |

| 31 | 30 | 0.41 | 5.67 | |||||||||||

| 41 | 40 | 0.38 | 4.9 | |||||||||||

| 51 | 50 | 0.35 | 4.56 | |||||||||||

| 81 | 80 | 0.31 | 4.25 | |||||||||||

| WF32 | 25 | 24 | 190 | 380 | 570 | 3000 | 4500 | 240 | 35 | 1.15 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 11 | 4.2 |

| 31 | 30 | 1.1 | 10.8 | |||||||||||

| 51 | 50 | 0.77 | 9.35 | |||||||||||

| 81 | 80 | 0.74 | 8.32 | |||||||||||

| 101 | 100 | 0.6 | 7.7 | |||||||||||

| WF40 | 25 | 24 | 320 | 640 | 960 | 3000 | 4000 | 377 | 50 | 1.35 | P1≤±1 P2≤±3 | P1≤±1 P2≤±3 | 13.2 | 6.6 |

| 31 | 30 | 1.32 | 12.96 | |||||||||||

| 51 | 50 | 0.92 | 11.22 | |||||||||||

| 81 | 80 | 0.81 | 9.84 | |||||||||||

| 121 | 120 | 0.72 | 8.4 | |||||||||||

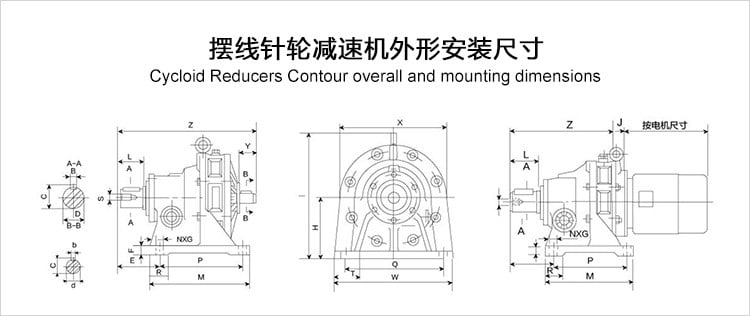

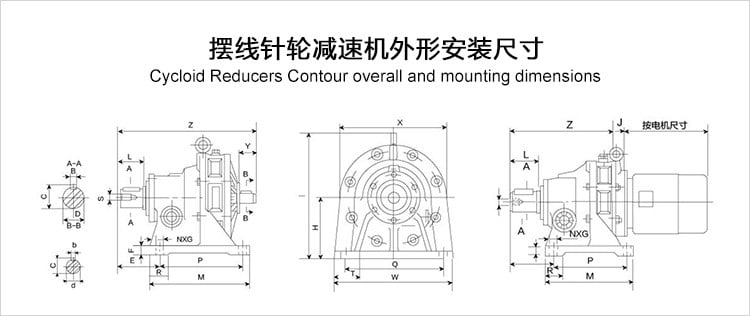

product drawings

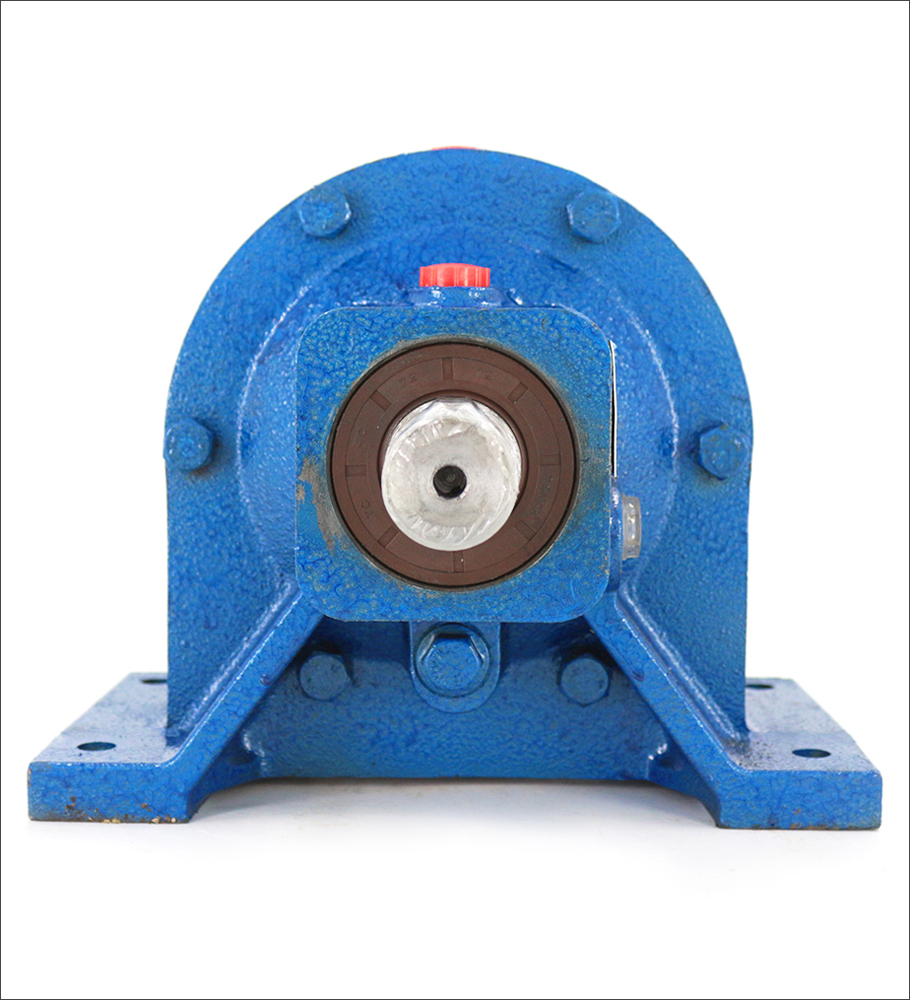

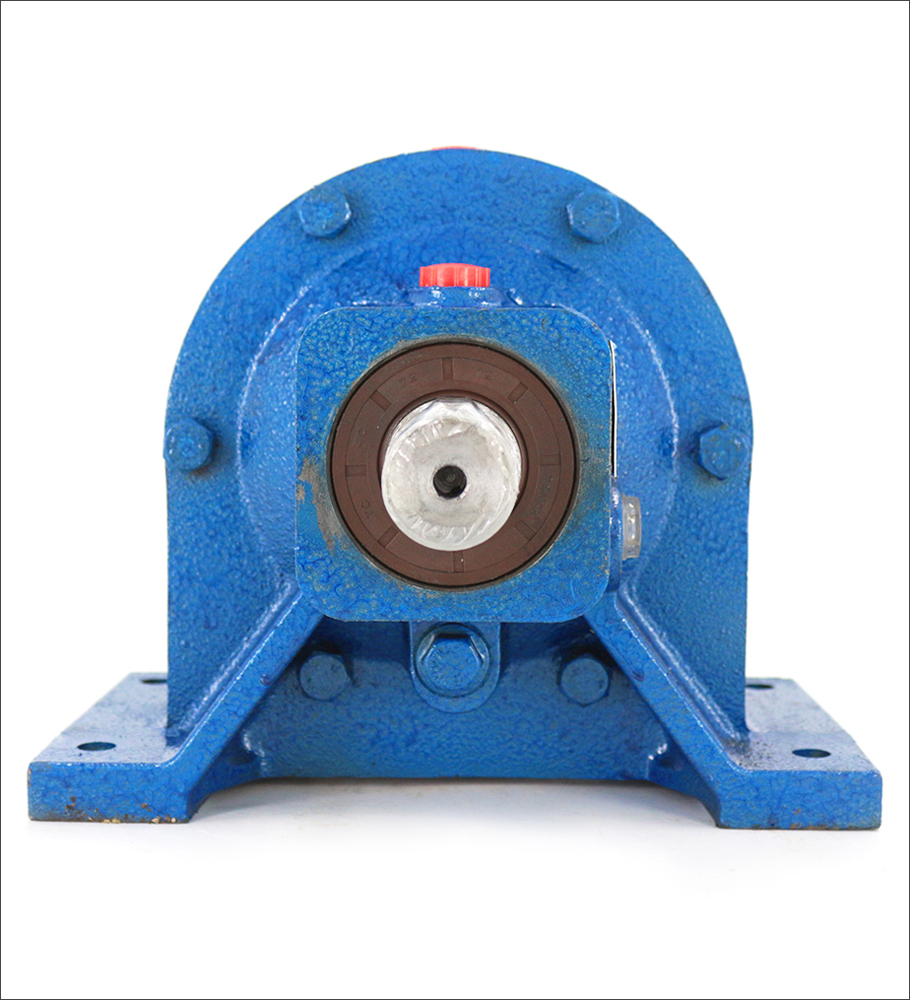

Detailed Photos

The reducer factory produces gearboxes with small size and high torque

advantages:

1, fine precision cycloidal structure

Ultra flat shape is achieved through differential reduction mechanism and thin cross roller bearing, contributing to the compact size of the equipment. The combination of small size and unmatched superior parameters achieves the best combination of performance, price and size (high cost performance).

2. Excellent accuracy (transmission loss ≤1 arcmin)

Through the complex meshing of precision cycloid gear and high precision roller pin, higher transmission accuracy is achieved while maintaining small size and high speed ratio.

3, high rigidity

Increase the mesh rate to disperse the load, so the rigidity is high.

4. High overload capacity

It maintains trouble-free operation under abnormally low noise and vibration conditions while ensuring excellent overturning and torsional stiffness parameters. Integrated axial radial cross roller bearings, high load capacity and overload capacity of the reducer, can ensure users to provide a variety of temperature range of applications.

5, the motor installation is simple

Electromechanical integration design, can be directly connected with the motor, any brand of motor can be installed directly, without adding any device.

6. Maintenance free

Seal grease to achieve maintenance free. No refueling, no mounting direction restrictions.

7, stable performance

The manufacturing process of high wear-resistant materials and high precision parts has been certified by ISO9000 quality system, which guarantees the reliable operation of the reducer.

Product Classification

WF Series

High Precision Miniature Reducer

WF series is a high precision micro cycloidal reducer with flange, which has a wide range of applications. This series of reducers includes precise reduction mechanisms and radial – axial roller bearings. The unique design allows load to act directly on the output flange or housing without additional bearings. WF series reducer is characterized by module design, can be installed through the flange motor and reducer, belongs to the motor directly connected reducer.

WFH Series

High Precision Miniature Reducer

WFH series is a hollow form of high precision miniature cycloidal reducer, wire, compressed air pipeline, drive shaft can be through the hollow shaft, non-motor direct connection type reducer. The WFH series is fully sealed, full of grease and includes precise deceleration mechanism and radial – axial roller bearings. The unique design allows load to be acted directly on the output flange or housing without additional bearings.

WR Series

high-precision corner reducer

The WR series is a flange output corner reducer. Like the WF and WFH series, it is a high-precision reducer (backlash less than 1 arc.min), and the level 2 can also be within 1 arc.min, which is higher than other types. Corner type reducer. It can replace the harmonic drive reducer, and its life and rigidity are more than 3 times that of the harmonic.

Installation Instructions

Company Profile

FAQ

Q:Are you a factory or a trading company ? where is your office ?

A:We are a company integrating industry and trade.The company is located at No. 101, Building F, HangZhou Industrial Park, No. 1 CZPT Street, Xiaobian Community, Chang’an Town, HangZhou City.

Q: What are your main products?

A: We currently have self-developed and manufactured planetary gearboxes, rv reducers, cycloidal gearboxes, hollow rotating platforms, steering gears, couplings and other products. You can view the specifications of the above products on our website, you can send us an email or leave a message, and our technical consultants will choose the product that suits you according to your needs.

Q: What’s your delivery time?

A: Generally speaking, it takes 15-30 days for our regular standard products, and it takes longer for customized products. But we are very flexible about the delivery time, it will depend on the specific order.

Q: Delivery time

A: Fubao has 2000+ production base, daily output of 1000+ units, standard models within 7 days of delivery.

Q: Reducer selection

A: Fubao provides professional product selection guidance, with higher product matching degree, higher cost performance and higher utilization rate.

Q: Application range of reducer

A: Fubao has a professional research and development team, complete category design, can match any stepping motor, servo motor, more accurate matching.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Agricultural Machinery, Humanoid Robot |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Any Direction |

| Customization: |

Available

| Customized Request |

|---|

Condition Monitoring of Cyclone Gearboxes

Whether you’re considering using a cycloidal gearbox in your home, office, or garage, you’ll want to make sure it’s made of quality material. You also want to make sure it’s designed properly, so it won’t be damaged by vibrations.

Planetary gearboxes

Compared to cycloidal gearboxes, planetary gearboxes are lighter and more compact, but they lack the precision and durability of the former. They are better suited for applications with high torque or speed requirements. For this reason, they are usually used in robotics applications. But, cycloidal gearboxes are still better for some applications, including those involving shock loads.

There are many factors that affect the performance of gearboxes during production. One of these is the number of teeth. In the case of planetary gearboxes, the number of teeth increases with the number of planets. The number of teeth is reduced in cycloidal gearboxes, which results in higher transmission ratios. These gearboxes also have lower breakaway torques, which means that they can be controlled more easily by the user.

A cycloid gearbox is comprised of three main parts: the ring gear, the sun gear, and the input shaft. The ring gear is fixed in the gearbox, while the sun gear transmits the rotation to the planet gears. The input shaft transfers motion to the sun gear, which in turn transmits it to the output shaft. The output shaft has a larger torque than the input shaft.

Cycloid gears have better torsional stiffness, lower wear, and lower Hertzian contact stress. However, they are also larger in size and require highly accurate manufacturing. Cycloid gears can be more difficult to manufacture than involute gears, which require large amounts of precision.

Cycloid gears can offer transmission ratios up to 300:1, and they can do this in a small package. They also have lower wear and friction, which makes them ideal for applications that require a high transmission ratio.

Cycloid gearboxes are usually equipped with a backlash of about one angular minute. This backlash provides the precision and control necessary for accurate movement. They also provide low wear and shock load capacity.

Planetary gearboxes are available in single and two-stage designs, which increase in length as stages are added. In addition to the two stages, they can be equipped with an optional output bearing, which takes up mounting space. In some applications, a third stage is also available.

Involute gears

Generally, involute gears are more complex to manufacture than cycloidal gears. For example, an involute gear tooth profile has a single curve while a cycloidal gear tooth profile has two curves. In addition, the involute curve is not within the base circle.

The involute curve is a very important component of a gear tooth and it can significantly influence the quality of contact meshing between teeth. Various works have been done on the subject, mainly focusing on the operating principles. In addition, the most important characteristic of the double-enveloping cycloid drive is its double contact lines between the meshing tooth pairs.

Cycloid gears are more powerful, less noisy, and last longer than involute gears. They also require less manufacturing operations during production. However, cycloid gears are more expensive than involute gears. Involute gears are more commonly used in linear motions while cycloid gears are used for rotary motions.

Although cycloid gears are more technically advanced, involute gears have the superior quality and are more aesthetically pleasing. Cycloid gears are used in various industrial applications such as pumps and compressors. They are also widely used in the watch industry. Nevertheless, involute gears have not yet replaced cycloid gears in the watch industry.

The cycloid disc has a number of pins around its outer edge, while an involute gear has only a single curve for the teeth. In addition, cycloid gears have a more robust and reliable design. Involute gears, on the other hand, have a cheaper rack cutter and less expensive involute teeth.

The cycloid disc’s transmission accuracy is about 98.5%, while the ring gear’s transmission accuracy is about 96%. The cycloid disc’s rotational velocity has a magnitude of 3 rad/s. A small change in the center distance does not affect the transmission accuracy. However, rotational velocity fluctuation can affect the transmission accuracy.

Cycloid gears also have the cycloid gear disc’s rotational velocity. The disc has N lobes. However, the cycloid gear disc’s transmission accuracy is still not perfect. This is because of the large rotational angles between the lobes. This also makes it difficult to manufacture.

Vibrations

Using modern techniques for vibration diagnostics and data-driven methods, this article presents a new approach to condition monitoring of cycloidal gearboxes. This approach focuses on detecting the root cause of gearbox failure. The article aims to provide a unified approach to gear designers.

A cycloidal gearbox is a high-precision gearbox that is used in heavy-duty machines. It has a large reduction ratio, which makes it necessary to have a very large input speed. Cycloid gears have high accuracy, but they are susceptible to vibration issues. In this article, the authors describe how a cycloidal gearbox works and how vibrations are measured. They also show how this gearbox can be used to detect faults.

The gearbox is used in positioners, multi-axis robots, and heavy-duty machines. The main characteristics of this gearbox are the high accuracy, the overload capacity, and the large reduction ratio.

There is little documentation on vibrations and condition monitoring of cycloidal gearboxes. The authors describe their approach to the problem, using a cycloidal gearbox and a testing bench. Their approach involves measuring the frequency of the gearbox with different input speeds.

The results show a good separation between the healthy and damaged states. Fault frequencies show up in the lower orders of frequencies. Faults can be detected using binning, which eliminates the need for a tachometer. In addition, binning is combined with Principal Component Analysis to determine the state of the gearbox.

This method is compared to traditional techniques. In addition, the results show how binning can be used to calculate the defect frequencies of the bearings. It is also used to determine the frequencies of the components.

The signals from the test bench are acquired using four sensors. These sensors are medium sensitivity 100 mV/g accelerometers. The signals are then processed using different signal processing techniques. The results show that the vibration signals are correlated with the internal motion of the gearbox. This information is used to identify the internal frequency of the transmission.

The frequency analysis of vibration signals is performed in cyclostationary and noncyclostationary conditions. The signals are then analyzed to determine the magnitude of the gear meshing frequency.

Design

Using precision gearboxes, servomotors can now control heavy loads at high speed. Unlike cam indexing devices, cycloidal gears provide extremely accurate positioning and high torque. They also provide excellent torsional stiffness and shock load capacity.

Cycloid gears are specially designed to minimize vibration at high RPM. Unlike involute gears, they are not stacked, which reduces friction and forces experienced by each tooth. In addition, cycloidal gears have lower Hertzian contact stress.

Cycloid gears are often used in multi-axis robots for positioners. They can provide transmission ratios as high as 300:1 in a compact package. They are also used in first joints in heavy machines. However, they require extremely accurate manufacturing. They are also more difficult to produce than involute gears.

A cycloidal gearbox is a type of planetary gearbox. Cycloid gears are specially designed for high gear ratios. They also have the ability to provide a large reduction ratio in a single stage. They are increasingly used in first joints in heavy machines. They are also becoming more common in robotics.

In order to achieve a large reduction ratio, the input speed of the gear must be very high. Generally, the input speed is between 500 rpm and 4500 rpm. However, in some cases, the input speed may be lower.

A cycloid is formed by rolling a rolling circle on a base circle. The ratio between the rolling circle diameter and the base circle diameter determines the shape of the cycloid. A hypocycloid is formed by rolling primarily on the inside of the base circle, while an epicycloid is formed by rolling primarily on the outside of the base circle.

Cycloid gears have a very small backlash, which minimizes the forces experienced by each tooth. These gears also have a good torsional stiffness, low friction, and shock load capacity. They also provide the best positioning accuracy.

The cycloidal gearbox was designed and built at Radom University. The design was based on three different cycloidal gears. The first pair had the external profile at the nominal dimension, while the second pair had the profile minus tolerance. The load plate had threaded screw holes arranged 15 mm away from the center.

editor by CX 2023-05-19

China manufacturer & factory supplier for single in Goma Democratic Republic of the Congo stage gear reducer for cooling tower fans With high quality best price & service

industrial factors including roller chains. Roller chains are accessible in common, nickel plated & stainless metal components in pitch dia. ranging from 1/4 in. to 3 in. Sorts consist of leaf chains in lacing configurations ranging from 2 x 2 to 8 x 8. Leaf chains are available in pitch measurements ranging from 1/2 in. to 2 in., pin dia. ranging from .156 in. to .687 in. & tensile strengths ranging from 4,000 lbs. to 156,000 lbs. Purposes include agricultural, conveyors, drilling, electronics assembly, food processing, fork elevate vehicles, hoists, packaging & textile equipment.Our merchandise are produced by modern computerized machinery and tools.a specialized supplier of a total assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Fast Particulars

- Relevant Industries:

-

Manufacturing Plant

- Model Title:

-

OEM

- Merchandise NO:

-

RV025~RV150 Reliable Shaft Input RV025~RV150 Attributes: 1. Top quality aluminum alloy gear box, mild bodyweight and not rust 2. 2 optional worm wheel supplies: Tin (Stannum) bronze or aluminum bronze alloy 3. Standard areas and very adaptable for shaft configurations and motor flange interface 4. A number of optional mounting alternatives 5. Reduced sound, Substantial efficiency in heat dissipation

SYF

- Product Number:

-

R

- cycloidal gearbox:

-

Cycloidal Gearbox Reducer

- Shade:

-

Blue

- Item title:

-

BLD Cycloid Speed Reducer

- Software:

-

Device Tool

- Content:

-

Aluminium Alloy

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

9-28800

Supply Capacity

- Provide Potential:

- 1200 Set/Sets for every Thirty day period Cycloidal pinwheel equipment pace reducer gearbox

Packaging & Shipping and delivery

- Port

- Shang hai

On the web Customization

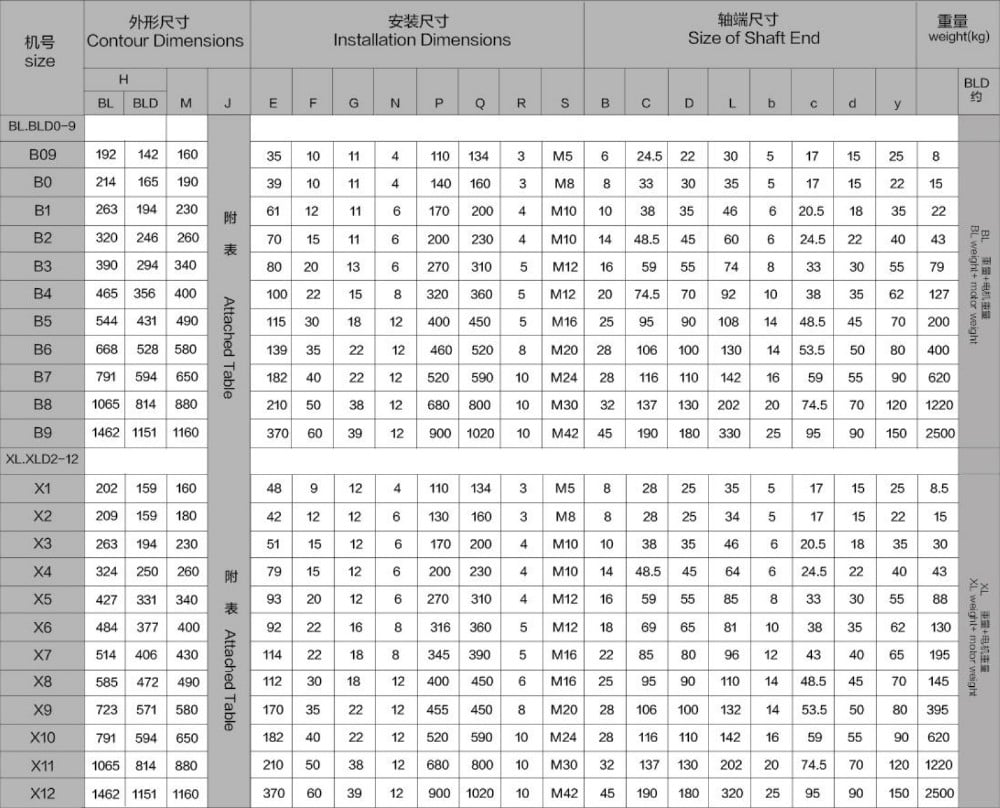

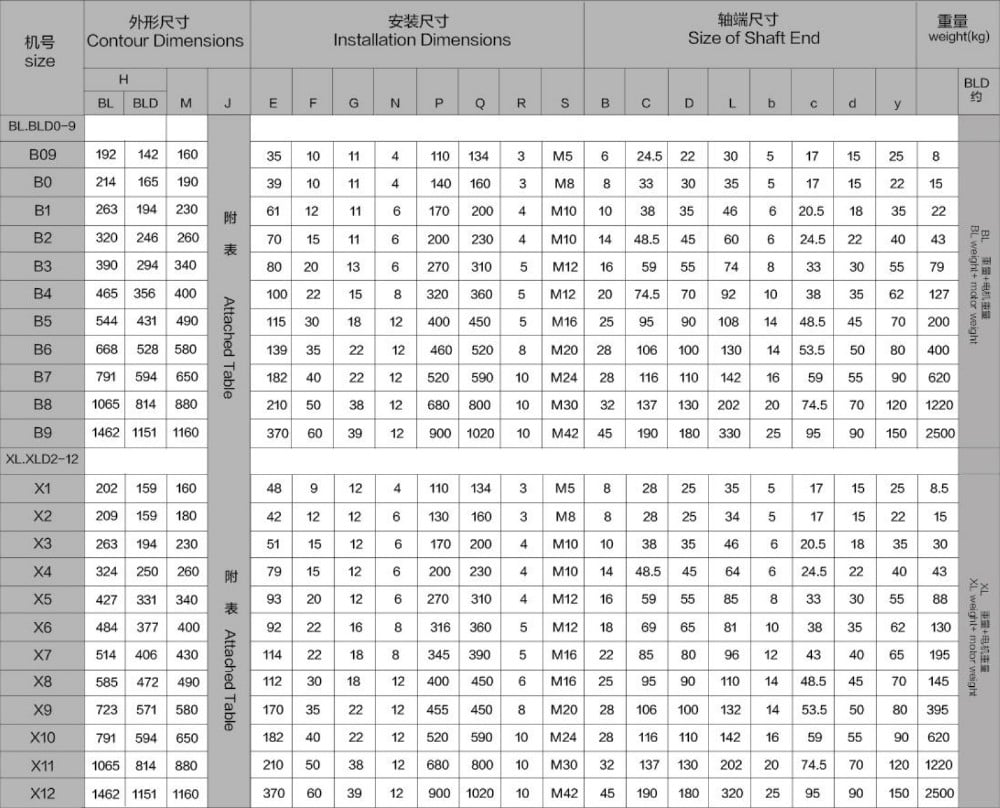

Product Description

Cycloidal equipment reducer is a theory adopted K-H-V Planetary Gear considerably less innovative equipment. Its transmission procedure as follows : input shaft outfitted with a 180-diploma dislocation of the double eccentric sets, changed with two eccentric flip as a roller bearing arm, the development of H-, two cycloid round hole at the centre shall uplink Eccentric Roller Bearings arm, which cycloidal gear needle spherical and meshing section, comprising a variation of the teeth meshing with the gearbox.

|

Type |

phase |

Product |

Ratio |

Nominal Electricity (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal Reducer |

One reducer |

B09/X1 |

9-87 |

.55-.eighteen |

26-50 |

|

B0/X2 |

one.1-.eighteen |

fifty eight-112 |

|||

|

B1/X3 |

.fifty five-.18 |

117-230 |

|||

|

B2/X4 |

four-.55 |

210-four hundred |

|||

|

B3/X5 |

eleven-.fifty five |

580-1010 |

|||

|

B4/X6/X7 |

11-2.2 |

580-1670 |

|||

|

B5/X8 |

eighteen.5-2.two |

1191-3075 |

|||

|

B6/X9 |

fifteen-5.five |

5183-5605 |

|||

|

B7/X10 |

11-45 |

7643 |

|

Kind |

stage |

Product |

Ratio |

Nominal Electricity (KW) |

Nominal Torque(N.m) |

|

X/B Series Cycloidal reducer |

Double reducer |

B10/X32 |

99-7569 |

.37-.18 |

one hundred seventy five |

|

B20/X42 |

one.1-.eighteen |

600 |

|||

|

B31/X53 |

two.2-.twenty five |

1250 |

|||

|

B41/X63 |

2.2-.25 |

1179-2500 |

|||

|

B42/X64 |

4-.fifty five |

2143-2500 |

|||

|

B52/X84 |

4-.fifty five |

2143-5000 |

|||

|

B53/X85 |

seven.5-.fifty five |

5000 |

|||

|

B63/X95 |

seven.5-.55 |

5893-8820 |

|||

|

B74/X106 |

11-2.2 |

11132-12000 |

|||

|

B84/X117 |

11-2.two |

11132-16000 |

Main Functions

All planetary cycloidal reducer rotating device can be divided into 3 parts:input component,deceleration part and output part.

Dislocation on the input shaft is outfitted with a 180℃ of double eccentric sleeve,geared up with two ball bearings on the eccentric sleeve,the formation of H two cycloid gear heart gap is the eccentric sleeve on the turning arm bearing raceway,and by a groud of cycloid gear and pin gear ring of equipment meshing,significantly less negative tooth meshing reduction mechanism to form,(in get to lessen friction,in small ratio of speed reducer,the needle with needle tooth on the equipment set).

When the enter shaft with eccentric sleeve rotation for a 7 days,as a end result of the cycloid equipment tooth profile curve traits and restricted by needle on the equipment tooth,the movement of the cycloid gear turning out to be the two revolution and rotation of the plane motion,and enter shaft are

made for a week,eccentric sleeve also flip the week,cycloid gear in the reverse direction around a massive tooth big difference reduction is received, then with the aid pf W output system,the cycloid equipment rotates at lower velocity motion by way of the pin shaft,handed to the output shaft,low output pace can be attained.

Traits:

1.Cycloid reducer massive reduction ratio, high performance: a reduction gear ratio is 9~87, the two-phase reduction equipment ratio is 121 ~ 5133, multistage combination can reach tens of thousandsClose up of two yokes with the common joint. Notice the slight oozing of grease from the UJ seal ends, the clump of grease is from within the yoke splined shaft spot –Generate (outer) yoke has a feminine (normal spline) gap and “Y” condition stop that is the common joint (UJ) mount. –UJ is a cross shaped casting getting roller bearings enclosed with caps at all four details and is held into the yoke with four “C” clips –Internal yoke and drive shaft is one more yoke welded to the generate stop, of the generate shaft. –Pushed shaft and inner yoke is the pushed shaft that rides inside of of the generate shaft and has a yoke welded at the driven finish –UJ another UJ as previously mentioned, and the needle tooth meshing line kind rolling friction, the meshing area no relative sliding, so a reduction effectiveness of ninety four%.

two.Pin wheel reducer clean running, lower noise: the enamel speak to at the very same time when in operation, the coincidence degree substantial, secure running, robust overload potential, low vibration and noise, a assortment of versions, little noise.

3. The use of trustworthy, prolonged life: since the main part is manufactured of substantial carbon alloy metal quenching (HRC58-62), and then grinding, and cycloid equipment and pin gear established mesh transfer to the pin gear kind rolling friction pair, friction coefficient is small, so that the meshing zone no relative sliding, use little, so resilient.

4. Compact framework, tiny volume: in contrast with other reducer with the power of the above bodyweight, modest volume 1/3, as is the planetary transmission, the enter shaft and the output shaft in the same axis, in buy to obtain the smallest attainable dimension.

Our Firm

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Tools Co., Ltd.is a reward company integrating development, layout, manufacturing and income,Primary marketing goods incorporate reducer motor,drinking water pump,construction machinery and elements,bearings,hardware and electrical gear,plastic merchandise,Labour protection appliance.Our business often adhere to the operation principle which includes folks-oriented, innovation as the soul,be geared up for danger in instances of peace, unremitting……

Software area

Certifications

Revenue territory

Packing & Shipping and delivery

|

Packaging |

|

|

Dimensions |

five hundred (L) * five hundred (W) * 400 (D) |

|

Excess weight |

1.2 T |

|

Packaging Particulars |

The typical bundle is picket box(Measurement: L*W*H). If export to european international locations,the picket box will be fumigated.If container is way too tigher,we will use pe movie for packing or pack it in accordance to buyers unique ask for. |

|

Packaging |

|

|

Dimension |

500 (L) * 500 (W) * four hundred (D) |

|

Fat |

1.2 T |

|

Packaging Details |

The regular package deal is wooden box(Size: L*W*H). If export to european nations around the world,the wood box will be fumigated.If container is also tigher,we will use pe film for packing or pack it in accordance to customers specific ask for. |

FAQ

Q1: Are you buying and selling business or manufacturer ?

A: We are a company in ZJ China.welcome to our manufacturing unit to have a pay a visit to.

Q2: How we select versions and requirements?

A:You can e-mail us the collection title & code (for example: WJ sequence worm gearbox) as nicely as requirement specifics, this sort of as motor electrical power, output velocity or ratio, support element or your software…as much knowledge as achievable. If you can provide some images or drawings, it is better.

Q3: How is your cost? Can you offer any price cut?

A: We will give the greatest value we can base on your demands and the quantities.

This fall: How extended ought to I wait around for the opinions right after I ship the enquiry?

A: Inside twelve hours.

Q5: What is your solution guarantee time period?

A:We provide one particular calendar year warranty considering that the vessel departure date still left China.

Q6: What industries are your gearboxes currently being used?

A:Our gearboxes are EPG is specialised in design and style, company and revenue of agricultural equipment and farm implements, which has an independent import and export legal rights. widely applied to metallurgical gear, mining products, automation tools, food equipment, packaging gear, tobacco products and so on.